Product Description

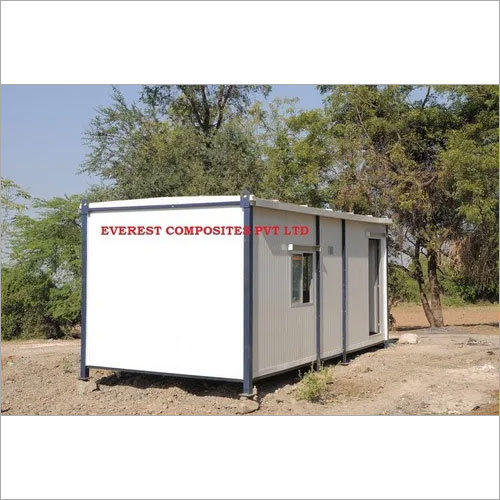

Accredited with an ISO 9001 certification, we are specialized in offering reliable Bunk House Banking on our rich industry experience, we are able to construct this house as per the specifications of our esteemed patrons. In order to achieve complete customer satisfaction, we ensure that adequate provisions are made for electricity and air ventilation in this house. Owing to our prompt installation of Bunk House and our ethical business practices, we have been successful in garnering several opportunities to serve our clients again.

Features:

Engineered for Demanding EnvironmentsThis bunk house is designed to withstand rigorous site conditions typical to gas pipeline projects. Its GI steel framework combined with sandwich panel insulation protects against temperature fluctuations and offers acoustic comfort. With high load-bearing floors and reinforced roof panels, it delivers reliability and safety to workers living on-site.

Flexible Modular ConstructionThe bolt & nut modular system allows for easy and quick assembly, disassembly, and relocation of the bunk house according to changing site needs. Single or double leaf doors and sliding windows enhance accessibility and ventilation, while customizable colors ensure the unit fits organizational branding or preference.

FAQs of Domestic Bunk House

Q: How is the Domestic Bunk House assembled and installed at the gas pipeline site?

A: The bunk house utilizes a bolt & nut modular system, enabling quick assembly and disassembly by skilled technicians. This process allows flexibility in installation, relocation, and expansion as per evolving site requirements.

Q: What materials are used for the walls, doors, and windows of the bunk house?

A: Walls comprise insulated sandwich panels (EPS, PU, or rockwool), doors are powder-coated mild steel for durability and security, and windows feature aluminum frames with glass and integrated mosquito nets. This blend offers both resilience and occupant comfort.

Q: When is it beneficial to use this type of modular bunk house?

A: These bunk houses are ideal for temporary or semi-permanent accommodation at gas pipeline construction sites, especially where rapid deployment, insulation, and adaptability to challenging environments are required.

Q: Where can the bunk house be customized in terms of design or color?

A: The exterior color of the bunk house, typically white and blue, can be customized on request to match company branding or site aesthetics. Additional options for internal layouts or features are also available upon consultation.

Q: What are the benefits of thermal and acoustic insulation in these bunk houses?

A: Thermal insulation helps maintain comfortable interior temperatures, reducing energy needs for heating or cooling, while acoustic insulation minimizes noise intrusion, enhancing overall living and working conditions for site personnel.

Q: How does the modular system contribute to the bunk houses usage and relocation?

A: The modular bolt & nut system simplifies both installation and dismantling, making it possible to move or reconfigure the bunk house with minimal effort, which is particularly advantageous in dynamic work environments.

Q: What safety standards are considered in the design of the bunk house?

A: The structure is engineered to support a floor load of 300 kg/m and adheres to roof load constraints (dead load: 50 kg/m, live load: 75 kg/m), ensuring the safety and longevity of the unit even under intensive site conditions.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese