Product Description

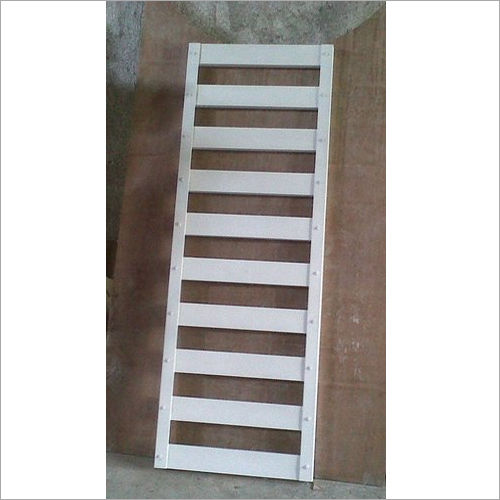

Our company is engaged in supplying FRP Lining On RCC-Civil that is highly demanded in the construction agriculture, water treatment, chemical, and similar industries. The lining is designed using high-quality and resistant materials like fiberglass and others. It is used by the workers to cover the RCC beams or walls. Besides, the provided FRP Lining On RCC-Civil is water, chemical, temperature, and pressure resistant, making it popular in the market. It is accessible in distinctive variants, sizes, models, and configurations to effectively fulfill varied construction requirements.

Product details

|

Material

|

FRP

|

|

Service

|

Linning

|

|

Surface Material

|

RCC

|

|

Technique

|

Pultrusion forming

|

|

Color

|

Blue

|

Superior Chemical Resistance and DurabilityFRP lining offers exceptional protection against acids, alkalis, and solvents, making it an ideal choice for harsh industrial environments. This advanced barrier system significantly improves the resistance of RCC tanks, vessels, and structures by preventing chemical-induced deterioration, thereby reducing maintenance frequency and prolonging service life.

Custom Fit for Varied ApplicationsOur FRP linings are completely customizable in terms of dimensions, color, and thickness, adapting perfectly to the shape and specifications of each surface. Whether its a flat, curved, or irregular substrate, our expert application ensures seamless coverage tailored for both functional and aesthetic needs.

Efficient On-site Installation ProcessThe FRP lining is applied directly at your site using technology like hand layup or spray up, followed by resin-coating for optimal bond strength and chemical resistance. Installation is managed by trained technicians, ensuring efficient execution with minimal disruption to ongoing operations. Ambient or heat curing options cater to site requirements and reinforce the longevity of the lining.

FAQs of FRP Lining On RCC-Civil:

Q: How is FRP lining applied to RCC or concrete surfaces?

A: FRP lining is applied directly to RCC or concrete surfaces on-site, typically using hand layup, spray up, or filament winding techniques. Skilled technicians first prepare the surface, then apply layers of FRP resin and glass mat, followed by curing under ambient or controlled heat conditions.

Q: What are the main benefits of using FRP lining on civil structures?

A: FRP lining provides excellent protection against corrosion, chemical attack, and leakage, significantly increasing the lifespan of RCC structures. It also offers high bond strength, low water absorption, customizable finishes, and resistance to a wide temperature range, making it a reliable and versatile solution for industrial environments.

Q: Where can FRP lining be used?

A: FRP lining is suitable for RCC structures, tanks, chemical vessels, industrial civil construction, and other surfaces exposed to aggressive chemicals or requiring enhanced durability. The system can be tailored for both new construction and retrofit projects, across varied industries.

Q: What customization options are available for FRP lining?

A: You can choose from various colors (grey, green, or custom), finishes (smooth, glossy, or semi-glossy), thicknesses (2 mm to 6 mm or as specified), and shapes (flat, curved, or site-specific designs). Dimension and chemical resistance are adjusted as per project requirements.

Q: How long does FRP lining last and what factors affect its lifespan?

A: The expected lifespan of FRP lining ranges from 10 to 20 years, depending on the exposure environment, chemical concentration, operating temperature, and regular maintenance. High-quality materials and expert installation further guarantee long-term performance.

Q: Is FRP lining resistant to fire and chemicals?

A: Yes, FRP lining is highly resistant to acids, alkalis, and solvents. Fire retardant properties can also be incorporated upon request, ensuring compliance with safety regulations in sensitive environments.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese