Product Description

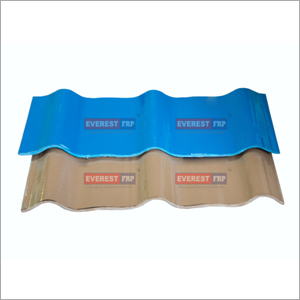

Discription -We are proud to introduce 100% automated machine made FRP panels with a gelcoat layer on top for the first time in India. We have disrupted the industry of FRP roofing and cladding panels by adding a fully automated manufacturing machine.

Gelcoat is a top coat for regular FRP panels with properties such as high percentage of UV resistance, high abrasive fill, and a better pigmentation of any colors for opaque panels. Clear gelcoat is also available for translucent skylight panels. With the addition of this top gel coat layer we have increased the life of this product to last for more than 20 years."

Features

- Lightweight and high-strength

- Excellent corrosion resistance

- Moisture Proof

- Chemical Resistance

- Wheather Proof

- Continuous laminating process

- Long Life

| Thickness- 1.8 mm to 6 mm |

Superior Durability and PerformanceEngineered for demanding environments, the one side gelcoated FRP sheet boasts high tensile strength exceeding 100 MPa and withstands temperatures from -40C to +120C. Its robust gelcoat surface offers enhanced resistance to impacts, chemicals, and UV exposure, ensuring longevity and consistent performance in both indoor and outdoor applications. Minimal maintenance means reduced operational costs and extended service life.

Flexible Customization for Diverse NeedsChoose from standard or custom sizes and a wide variety of colors to complement specific project requirements. Thickness options (1mm-3mm) and fire-retardant features can be tailored to safety codes and design aesthetics. With its ability to deliver on unique specifications, this FRP sheet fits perfectly in new builds or retrofit projects across industrial and commercial segments.

Optimal Thermal and Moisture ProtectionFRP's low heat transfer coefficient guarantees excellent thermal insulation, making these sheets ideal for maintaining interior climates in various settings. Their dense composition further ensures very low water absorption, protecting structures from moisture-related damage and promoting long-term stability in changing weather conditions.

FAQ's of FRP One Side Gelcoated Sheet:

Q: How is the FRP One Side Gelcoated Sheet applied in construction projects?

A: These sheets are commonly used for cladding, roofing, wall paneling, and partitions. Installation involves fixing the flat sheets onto supporting frames or surfaces, depending on the application's requirements, ensuring a smooth, glossy, and durable finish.

Q: What customization options are available for color, size, and thickness?

A: You can choose white as the default color or request custom colors to match your design scheme. Sizes are available up to 8 feet long and 4 feet wide, with thickness ranging from 1 to 3 mm. Custom sizing and performance options are accommodated to meet specific project needs.

Q: What are the benefits of the gelcoated surface on the FRP sheet?

A: The gelcoated finish provides enhanced gloss, improved resistance to impact and chemicals, easy cleaning, and strong adhesion. It also contributes to a visually appealing, plain smooth surface that remains durable under harsh conditions.

Q: When is fire retardancy recommended for these sheets?

A: Fire retardancy is recommended for environments where enhanced safety standards are required, such as industrial factories, commercial buildings, or high-occupancy spaces. You may request fire retardant properties during your order to comply with local regulations.

Q: Where can these FRP sheets be sourced or supplied?

A: They are manufactured, exported, and supplied by reputable companies in India, offering both standard and customized solutions for domestic and international clients.

Q: What process is used to manufacture the sheets and ensure strong gelcoat adhesion?

A: The FRP sheets are molded with a gelcoated layer applied to one side, utilizing advanced molding techniques to achieve a strong bond and seamless finish that enhances durability and impact resistance.

Q: How does the sheet's thermal insulation and water resistance contribute to its usage?

A: The sheet's low heat transfer coefficient provides superior thermal insulation, maintaining stable indoor conditions. Very low water absorption safeguards structures from moisture ingress, making it ideal for areas vulnerable to humid or thermal fluctuations.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese