Product Description

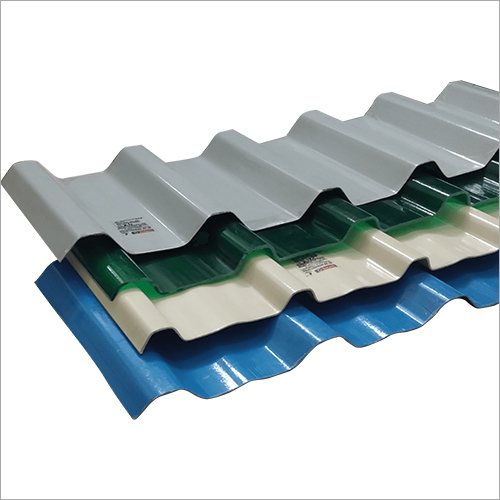

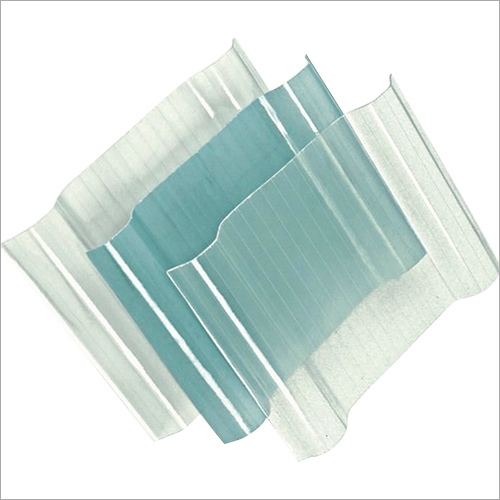

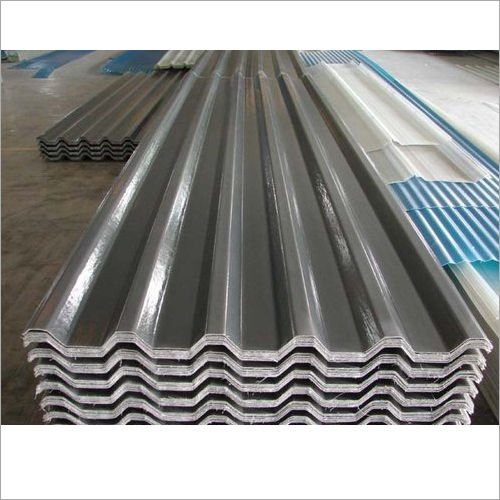

Gelcoated FRP panels are a type of Fiberglass Reinforced Plastic (FRP) panel that has a smooth and glossy surface finish. The gelcoat is a thin layer of resin that is applied to the surface of the FRP panel during the manufacturing process. The gelcoat layer provides several benefits to the FRP panel, including improved durability, scratch resistance, and UV resistance. It also enhances the aesthetics of the panel, giving it a glossy and professional appearance.

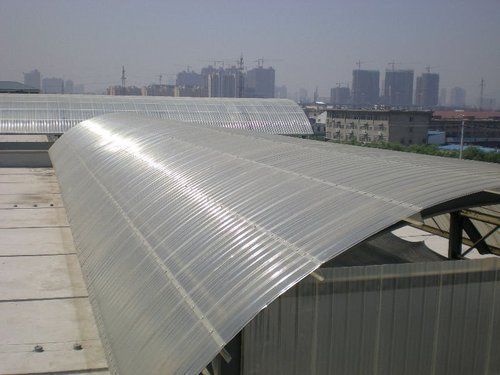

Gelcoated FRP panels are commonly used in architectural and design applications, such as wall and ceiling panels, partitions, and decorative elements. They are also used in transportation, marine, and industrial applications where a high-quality and durable surface finish is required. Overall, gelcoated FRP panels offer a cost-effective and low-maintenance alternative to traditional building materials such as metal, wood, and concrete. They are lightweight, strong, and durable, with high resistance to impact, corrosion, and weathering. Additionally, their smooth and glossy surface finish makes them an attractive option for a wide range of applications.

FAQs of Gelcoated FRP Panels:

Q: What are Gelcoated FRP Panels made of?

A: Gelcoated FRP Panels are made of FRP (Fiberglass Reinforced Plastic) material.

Q: What is the standard size of Gelcoated FRP Panels?

A: The standard size of Gelcoated FRP Panels is provided for industrial usage.

Q: What surface treatment is applied to Gelcoated FRP Panels?

A: Gelcoated FRP Panels are polished to ensure a smooth and glossy surface finish.

Q: Can Gelcoated FRP Panels be used for industrial applications?

A: Yes, Gelcoated FRP Panels are specifically designed for industrial use due to their material and properties.

Q: In what colors are Gelcoated FRP Panels available?

A: Gelcoated FRP Panels are available in a multicolor range to suit various aesthetic preferences.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese