Product Description

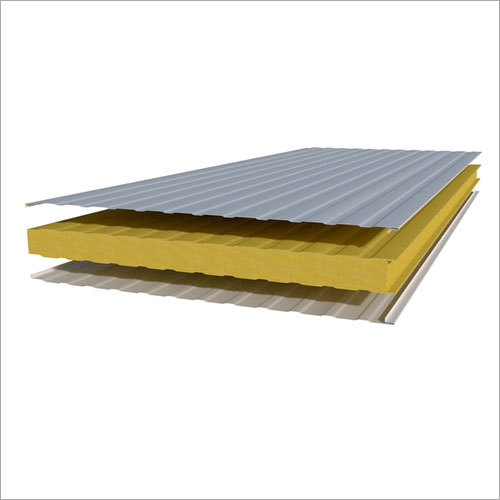

Sandwich Panel is used to enhance thermal and acoustic insulation properties of cold rooms, food processing plants and refrigerated rooms. Advanced technology is followed to design sealing parts and joints of this panel to enhance thermal attributes of a specific structure. Provided Sandwich Panel is suitable for roof and wall insulation purpose. Light in weight, this panel can be installed quickly. Excellent mechanical attributes, uniform surface finish, decay proof design and reasonable price are the key aspects of this insulation material. Excellent rigidity level, long lasting quality, non-porous design and chemical protection capacity have made it the most sought after roof and wall insulation solutions in the market.

Product details

| Center Part | Metal |

| Shape | Wavy, Sandwiched |

| Technique | Cold Rolled,Hot Rolled,Clear Glass |

| Surface Treatment | Coated,Galvanised,Film Coated |

| Material | FRP |

With a core density of 38-42 kg/m and a sound reduction index above 25 dB, these sandwich panels excel in thermal insulation, soundproofing, and structural integrity. The robust PUF core combined with PPGI facings ensures each panel can withstand demanding industrial conditions, offering both longevity and consistent performance.

Customizable Dimensions & ApplicationPanels are manufactured with a coverage width of 1000mm and cut to custom lengths up to 12 meters, accommodating diverse architectural demands. Choose from various thicknesses (30-100mm), shapes, and colors, including white, blue, off-white, or any custom hue, for a tailored fit in projects such as refrigeration units, wall cladding, or roofing solutions.

FAQs of Sandwich Panel:

Q: How are sandwich panels installed for industrial or commercial buildings?

A: Sandwich panels are typically installed using a continuous line or molding process. Panels are placed on the prepared structural framework, fastened at the joints, and sealed for a waterproof finish. Their lightweight nature simplifies handling and speeds up installation, reducing labor and construction time.

Q: What makes these sandwich panels effective for thermal and sound insulation?

A: The polyurethane foam (PUF) core, with its density of 38-42 kg/m, provides exceptional thermal conductivity (0.022-0.024 W/mK) and a sound reduction index above 25 dB. This combination minimizes both heat transfer and noise infiltration, making them ideal for temperature- and acoustically-sensitive environments.

Q: Where can these insulated sandwich panels be applied?

A: These panels are suitable for a range of applications including industrial sheds, warehouses, prefabricated buildings, cold storage facilities, and both roofing and wall cladding. Their versatility is enhanced by their waterproof, thermal, and acoustic properties.

Q: What customization options are available for color and size?

A: Customers can select panels in standard colors like white, blue, and off-white, or request customized colors. The panel length can be tailored up to 12 meters and thickness ranges from 30mm to 100mm, allowing for flexibility in design and architectural requirements.

Q: What is the process used in the manufacturing of these sandwich panels?

A: Manufacturing employs techniques such as continuous line production, injection molding, and lamination. High-quality PUF is injected between pre-painted galvanized iron (PPGI) facings, followed by color coating or galvanization for added protection and enhanced finish.

Q: When should insulated sandwich panels be preferred over conventional building materials?

A: Sandwich panels are an excellent choice when energy efficiency, rapid installation, and low maintenance are priorities. They outperform traditional materials in applications that demand insulation, fire resistance, and lightweight construction, such as cold rooms, warehouses, and prefabricated buildings.

Q: What are the key benefits of using these sandwich panels in construction?

A: Key benefits include superior thermal and acoustic insulation, fire retardance, lightweight design, quick installation, and customization in size and color. These features contribute to energy savings, improved working environments, and long-lasting durability.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese