Product Description

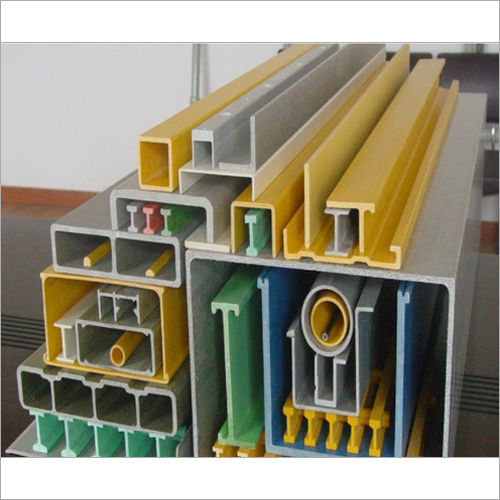

When a building is being constructed, it needs stronger and dimensionally stable beams to support the entire structure. Therefore, the construction workers use our FRP Trench Products that enable them to create dimensionally stable, stronger, and resistant beam to erect floor above the beams. These products are designed in metal structures and different sections. They are easy to lay and install for various construction projects. The delivered FRP Trench Products are essentially outlined to support concrete, asphalt, and similar materials without affecting the overall structure.

Product details

|

Material

|

FRP

|

|

Performance

|

Anti-corrosion and anti-aging

|

|

Shape

|

Hollow

|

|

Technique

|

Molded

|

|

Color

|

Transparent,Blue,Natural,White

|

Customizable Solutions for Every ProjectOur FRP trench products come in a variety of colors, sizes, and shapesincluding standard and customized dimensionsensuring flexible solutions for different industrial environments. With available gel coating, smooth finishes, and anti-corrosive treatments, these trench covers and gratings can be tailored precisely to your operational needs.

Built for Safety and DurabilityThanks to the use of premium E-glass fibers and 800 to 1500 GSM, our FRP trench products deliver high load-bearing capacity and superior mechanical strength. Fire-resistant (self-extinguishing and ASTM E84 compliant), highly impact-resistant, and excellent in UV and electrical insulation performance, these covers are ideal for both indoor and outdoor applications.

Versatile Applications Across IndustriesSpecifically designed for industrial drainage systems, cable management, walkways, and heavy-duty trench covers, our products withstand demanding operational conditionssupporting temperatures up to 120C, and resisting water absorption. Indian and ASTM standards are met or exceeded, positioning us as a trusted exporter, manufacturer, and supplier across India.

FAQs of FRP Trench Products:

Q: How do FRP trench products benefit industrial drainage and cable management systems?

A: FRP trench products offer exceptional durability, high load-bearing limits (up to 40 tons), and resistance to water, fire, and chemicals. Their superior electrical insulation and long life span ensure safe, efficient operation for industrial drainage and cable management applications.

Q: What customization options are available for FRP trench covers?

A: We offer a wide range of customization, including colors (grey, green, or tailored to project needs), dimensions (L*W*H), shapes (rectangular and custom profiles), thickness (5 mm to 50 mm), and surface treatments like gel coating and anti-corrosive finishes to match specific requirements.

Q: Where can FRP trench products be installed?

A: These products are suitable for installation in industrial areas, manufacturing plants, utility corridors, electrical substations, outdoor walkways, and any environment demanding robust, non-conductive, and weather-resistant trench covers or gratings.

Q: What is the manufacturing process for these FRP trench products?

A: Our trench covers and gratings are produced using the pultrusion moulding technique, which ensures consistent mechanical properties, uniform density (1.7 g/cm), and high strength by aligning E-glass fibers with resin through a controlled process.

Q: When should you choose FRP trench covers over traditional materials?

A: Select FRP trench covers when you require corrosion resistance, electrical safety, low thermal conductivity, excellent UV protection, and significant reduction in maintenance compared to concrete or steel products, especially in harsh or outdoor environments.

Q: How do FRP trench covers ensure safety in high-temperature or corrosive environments?

A: These covers are tested to operate at temperatures up to 120C, feature anti-corrosive surface treatments, and have self-extinguishing fire-resistant properties conforming to ASTM E84. This makes them reliable for environments with fluctuating temperatures or exposure to chemicals.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese